Q195 Galvanized square pipe

Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating.

PRODUCT DESCRIPTION

Square tube is formed from coil and then ran through a series of dies. It’s welded from the inside to form its shape. Square tubes are generally used for maintenance and structural purposes.

Some examples of square tubing applications would be building construction, railings, and sign posts. They are measured by their outside dimensions and their wall thickness.

Square Tube is available in the following metal types:

Alloy Steel

Mild Stee

Carbon Steel

Stainless Steel

Square tube has similar uses to RHS and is used for both industrial and construction applications. Square section RHS is available in the same thicknesses as RHS and dimensions range from 20 mm x 20 mm to 400 mm x 400 mm.

Specification

|

Size by Inch (diameter) |

Thickness |

Sizes by MM (diameter) |

Thickness |

|

inch |

inch |

mm |

mm |

|

1/2″ x 1/2″ |

0.065″ |

16mm×16mm |

0.4mm~1.5mm |

|

3/4″ x 3/4″ |

0.049″ |

18mm×18mm |

0.4mm~1.5mm |

|

0.065″ |

20mm×20mm |

0.4mm~3mm |

|

|

0.083″ |

22mm×22mm |

0.4mm~3mm |

|

|

0.120″ |

25mm×25mm |

0.6mm~3mm |

|

|

1″ x 1″ |

0.049″ |

30mm×30mm |

0.6mm~4mm |

|

0.058″ |

32mm×32mm |

0.6mm~4mm |

|

|

0.065″ |

34mm×34mm |

1mm~2mm |

|

|

0.072″ |

35mm×35mm |

1mm~4mm |

|

|

0.083″ |

38mm×38mm |

1mm~4mm |

|

|

0.095″ |

40mm×40mm |

1mm~4.5mm |

|

|

0.109″ |

44mm×44mm |

1mm~4.5mm |

|

|

0.120″ |

45mm×45mm |

1mm~5mm |

|

|

1 1/8″ x 1 1/8″ |

0.035″ |

50mm×50mm |

1mm~5mm |

|

0.049″ |

52mm×52mm |

1mm~5mm |

|

|

0.065″ |

60mm×60mm |

1mm~5mm |

|

|

0.109″ |

70mm×70mm |

2mm~6mm |

|

|

0.120″ |

75mm×75mm |

2mm~6mm |

|

|

1 1/4″ x 1 1/4″ |

0.049″ |

76mm×76mm |

2mm~6mm |

|

0.065″ |

80mm×80mm |

2mm~8mm |

|

|

0.072″ |

85mm×85mm |

2mm~8mm |

|

|

0.083″ |

90mm×90mm |

2mm~8mm |

|

|

0.109″ |

95mm×95mm |

2mm~8mm |

|

|

0.120″ |

100mm×100mm |

2mm~8mm |

|

|

0.135″ |

120mm×120mm |

4mm~8mm |

|

|

0.156″ |

125mm×125mm |

4mm~8mm |

|

|

0.188″ |

130mm×130mm |

4mm~8mm |

|

|

1 1/2″ x 1 1/2″ |

0.049″ |

140mm×140mm |

6mm~10mm |

|

0.065″ |

150mm×150mm |

6mm~10mm |

|

|

0.072″ |

160mm×160mm |

6mm~10mm |

|

|

0.083″ |

180mm×180mm |

6mm~12mm |

|

|

0.109″ |

200mm×200mm |

6mm~30mm |

|

|

0.120″ |

220mm×220mm |

6mm~30mm |

|

|

0.140″ |

250mm×250mm |

6mm~30mm |

|

|

0.188″ |

270mm×270mm |

6mm~30mm |

|

|

0.250″ |

280mm×280mm |

6mm~30mm |

|

|

1 3/4″ x 1 3/4″ |

0.065″ |

300mm×300mm |

8mm~30mm |

|

0.083″ |

320mm×320mm |

8mm~30mm |

|

|

0.095″ |

350mm×350mm |

8mm~30mm |

|

|

0.109″ |

380mm×380mm |

8mm~30mm |

|

|

0.120″ |

400mm×400mm |

8mm~30mm |

|

|

0.188″ |

420mm×420mm |

10mm~30mm |

|

|

2″ x 2″ |

0.049″ |

450mm×450mm |

10mm~30mm |

|

0.065″ |

480mm×480mm |

10mm~30mm |

|

|

0.083″ |

500mm×500mm |

10mm~30mm |

|

|

0.109″ |

550mm×550mm |

10mm~40mm |

|

|

0.120″ |

600mm×600mm |

10mm~40mm |

|

|

0.145″ |

700mm×700mm |

10mm~40mm |

|

|

0.165″ |

800mm×800mm |

10mm~50mm |

|

|

0.188″ |

900mm×900mm |

10mm~50mm |

|

|

0.250″ |

1000mm×1000mm |

10mm~50mm |

|

|

0.312″ |

|||

|

2 1/4″ x 2 1/4″ |

0.188″ |

||

|

0.250″ |

|||

|

2 1/2″ x 2 1/2″ |

0.083″ |

||

|

0.109″ |

|||

|

0.120″ |

|||

|

0.188″ |

|||

|

0.250″ |

|||

|

0.312″ |

Dimensional Tolerances

| Dimensional Tolerances | |||

| Outside Diameter: | Twist: | Maximum twist per 3 feet of length | |

| Largest outside dimension | Outside tolerance including convexity and concavity | Longest outside dimension | |

| up to 2 1/2″ | ±.020″ | 2″ to 2 1/2″inclusive | .062″ |

| over 21/2″ to 31/2″ inclusive | ±.025″ | over 21/2″ to 4″ inclusive | .075″ |

| over 31/2″ to 51/2″ inclusive | ±.030″ | over 4″ to 6″ inclusive | .087″ |

| over 51/2″ | ±1% | over 6″ to 8″ inclusive | 100″ |

| Tolerances include allowance for convexity or concavity. For rectangular sections, the tolerance calculated for the larger flat dimension shall also apply to the smaller flat dimension. This tolerance may be increased 50 percent when applied to the smaller dimension, if the ratio of cross sectional dimension is between 1.5 and 3, and 100 percent when the ratio exceeds 3. |

over 8″ | 112″ | |

| Straightness: Permissable variation shall be 1/8″ times the number of feet of total length divided by 5: |

|||

| .125″ x (total length) ÷ 5 | |||

| Wall Thickness: | Squareness of Sides: | ||

| Maximum allowable variation | ±10% | Adjacent sides may deviate from 90° by a tolerance of plus or minus 2 degrees maximum. | |

| (wall thickness is to be measured at the center of the flat, exclusive of the weld area, and not at the corners) |

|||

| Worner Radii: | Flash: | ||

| The radius of any outside corner shal not exceed three times the specified wall thickness |

Structural tubing usually is supplied flash-in. The height of the flash will vary with the wall thickness of the tube. |

||

ASTM A500 Cold Formed Welded and Seamless Carbon Steel Steel Structural Tubing in Round and Shapes

| Grade Designation | Chemistry-Ladle Analysis | |||

| Carbon | Manganese | Phosporous | Sulfur | |

| A501 (A36) | 0.26% max | – | 0.04% max | 0.05% max |

| A500A | 0.26% max | – | 0.04% max | 0.05% max |

| A500B | 0.26% max | – | 0.04% max | 0.05% max |

| A500C | 0.23% max | 1.35% max | 0.04% max | 0.05% max |

| Copper, when copper steel is specified, 0.20% minimum. | ||||

| Mechanical Properties | ||||

| Grade Designation | Grade | Tensile Strength | Yield Strength Minimum | Elongation In 2 Inches Minimum |

| Condition | Minimum | |||

| A501 (A36) | Hot Formed | 58,000 psi | 36,000 psi | 23% |

| A500A | Cold Formed | 45,000 psi | 39,000 psi | 25% |

| A500B | Cold Formed | 58,000 psi | 46,000 psi | 23% |

| A500C | Cold Formed | 62,000 psi | 50,000 psi | 21% |

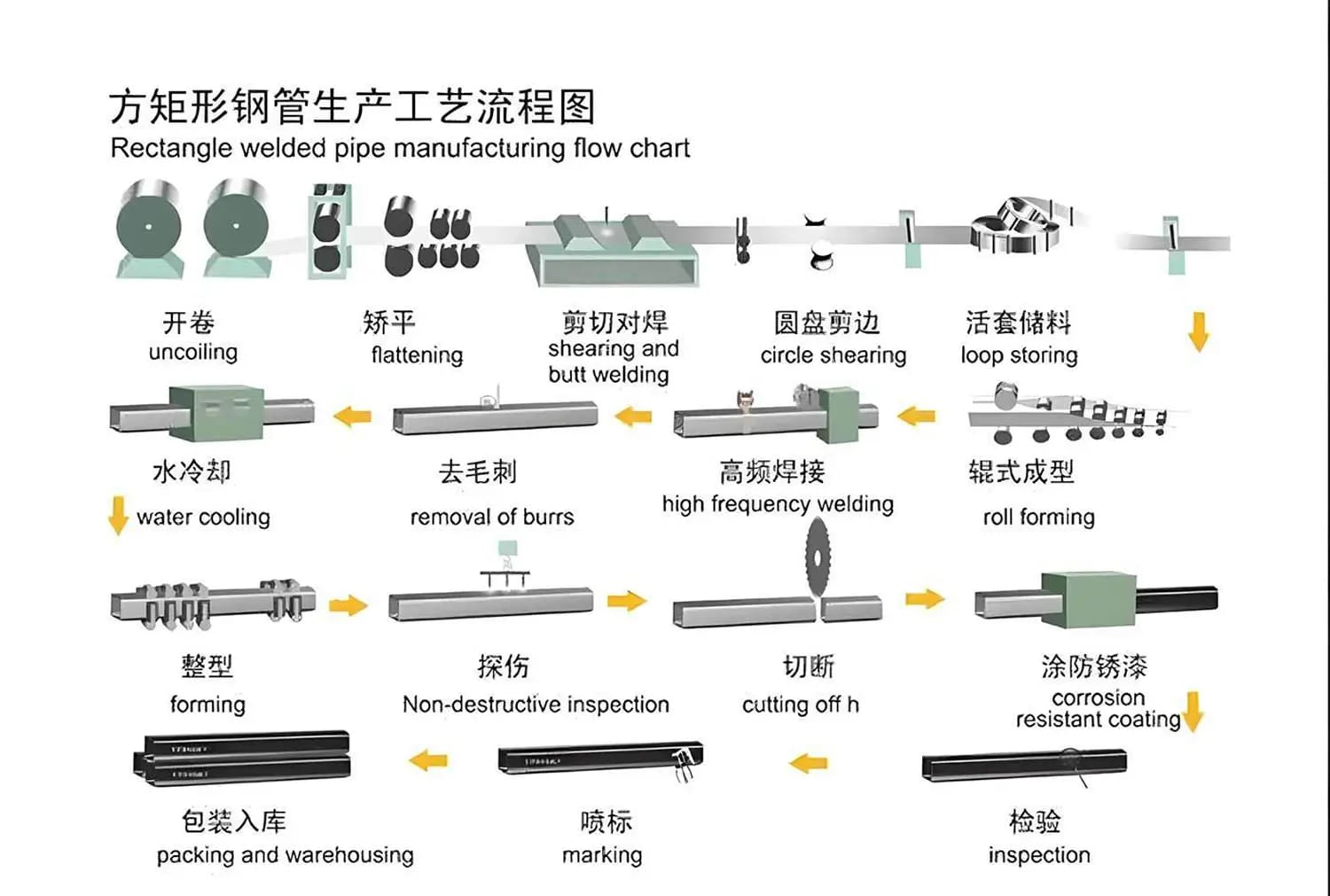

Packing and shipping

Our products are exported to more than 60 countries and regions including Europe, the Middle East, Southeast Asia, Australia, etc. We promise”complete specifications, prompt delivery, high quality, competitive price, “The unwavering supports you provide, along with the increasing requirements you put contributes to more varied high-quality products with more competitive prices we offer.

It has scale advantages, resource advantages, integration advantages, technology research and development advantages, capital operation advantages, and has a complete pre-sales, sales and after-sales service system. We continue to innovate and seek transformation, and are willing to provide better services to customers around the world.

Application field

BAOSTEEL NEW MATERIALS GROUP CO.,LIMITED is a modern integrated steel service enterprise specializing in steel products processing, sales and technical services.The products are widely used in water conservancy projects, military equipment, construction industry, aerospace, automobiles, home appliances and other fields.

ADVANTAGE

ATTRACTNVEAND REASONABLE PRICE

We have our own manufacture, which means we cangive you a very competitive price in the industry

SPECIALZED MANUFAGTURERS

Specializes in manufacturing and selling thehigh-quality stainless steel, choose us we can offer you the best stainless steel products

15 YEARS' EXPERIENCE

With years' experience in the line, we are readyto provide with best service and high-qualityproducts in timely delivery

PROFESSIONAL TEAM

Our professional engineering and technicalteam has extensive knowledge in the stain- less steel manufacturing industry

FAQ

Our Service Commitment

A:Our price is very competitive because we are a factory. Pls feel free to contact us if you are interested in our products.

A:Of course, we welcome customers from all over the world to visit our factory.

Provide the assembly assembly drawing of the lifting platform for free

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed.we accept the third party inspection absolutely.

A:Within 15-45 days after we confirm you requirement.

A: Exported to more than 80 countries mainly from America, Canada, Brazil, Chile, Colombia, Russia, Ukraine, Thailand, Myanmar, Vietnam, United Arab Emirates and etc.

A: We ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

A:Yes absolutely we accept.

RELATED PRODUCTS

Get in Touch

Dedicated to helping clients solve their most products challenging products and technology issues. Please complete the form below, and our sales team will be in touch with you shortly. Receive regular industry updates and product design tips straight to your inbox.

- +86 15020871633

- +86 15020871633

- +86 15020871633

- sales@baosteelmaterial.com